The rotor of the motor is put into the hot jacket of shaft

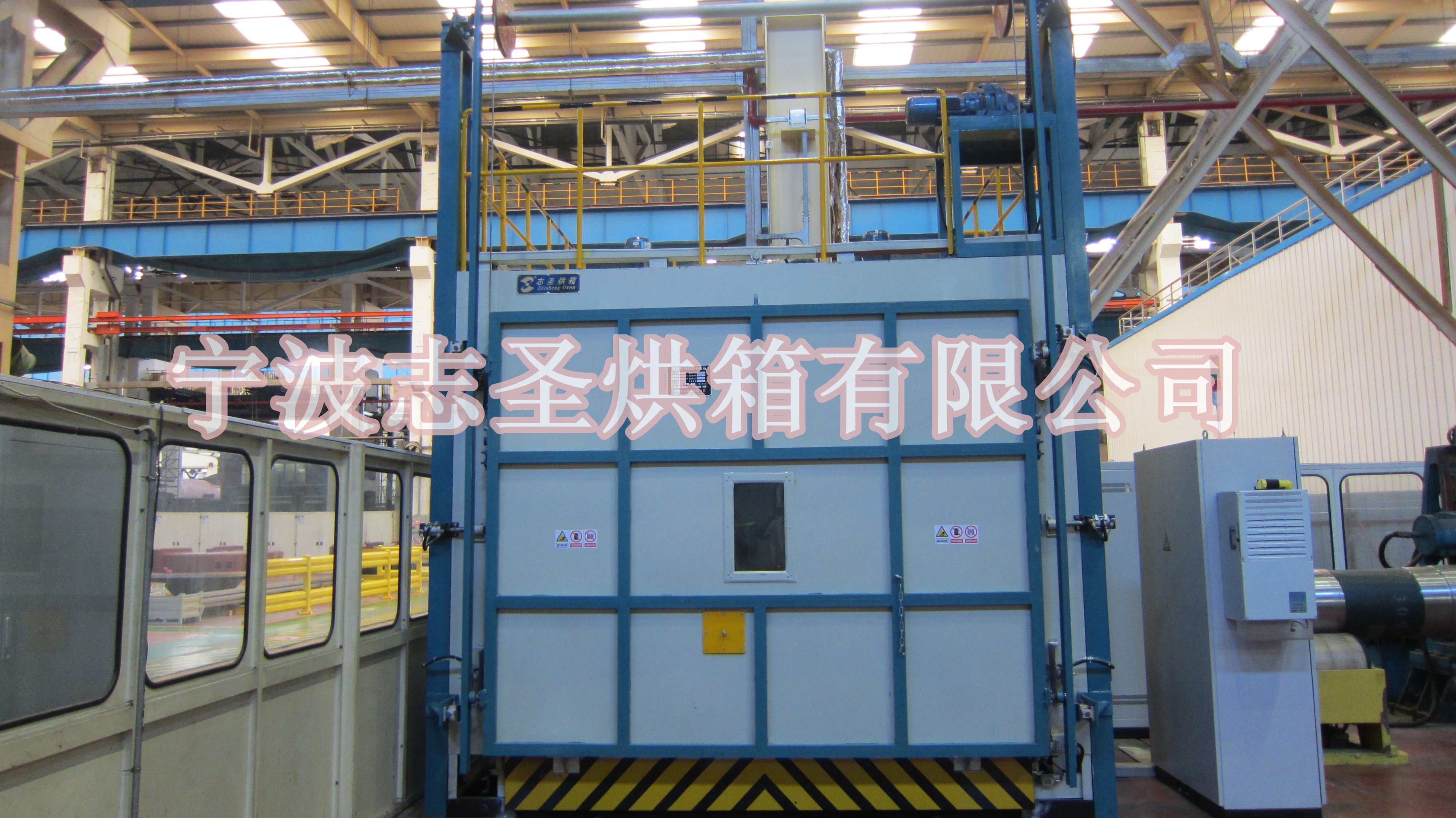

The assembly process of interference heat jacket between small and medium-sized motor aluminum shell and stator coil, motor transmission shaft and bearing

Wire removal furnace is mainly used for insulating paint of ablative coil in the process of motor repair, which eliminates the bad environment and danger of traditional wire burning.

The temperature rise of the furnace surface is at most 20 ℃ plus indoor temperature. For special position, please refer to standard JB/T5520-91;

Advanced hot air circulation system ensures good temperature uniformity in the cabinet;

The inner liner is made of high-quality SUS304 stainless steel and equipped with thermal expansion joint. The inner liner will not deform at high temperature and is durable;

Door diversity: top door translation, flip optional; lateral movement of the front door and vertical lifting are optional;

Manual, electric and hydraulic door opening modes are optional; single and double layers of gate structure are optional;

Heating mode: electric heating, gas heating and fuel oil heating.

| Parameter | HA-1R/HA-1C | HA-2R/ HA-1C | HA-3R/ HA-1C | HA-4R/ HA-1C |

| Dimension of working chamber (width x depth x height)mm | 800×800×1000 | 1500×2000×1500 | 2000×3000×2000 | 2200×4000×2000 |

| Operating temperature(℃) | Indoor temperature --450 | Indoor temperature --450 | Indoor temperature --450 | Indoor temperature --450 |

| Operating voltage/frequency (V/ Hz) | 3-380/50 | 3-380/50 | 3-380/50 | 3-380/50 |

| Heating power (kw) | 18 | 40 | 63 | 90 |

| Lift-up door power(kw) | — — | 0.25 | 0.75 | 0.75 |

| Trolley driving power(kw) | — — | 0.25 | 0.75 | 1.5 |

| Temperature uniformity(%) | ±2.5 | ±2.5 | ±2.5 | ±2.5 |

| Temperature fluctuation(℃) | ±1 | ±1 | ±1 | ±1 |

| Weight(T) | 0.55 | 3 | 4.5 | 6 |

Note:Non-standard products can be designed and manufactured in accordance with the requirement of the user. | ||||