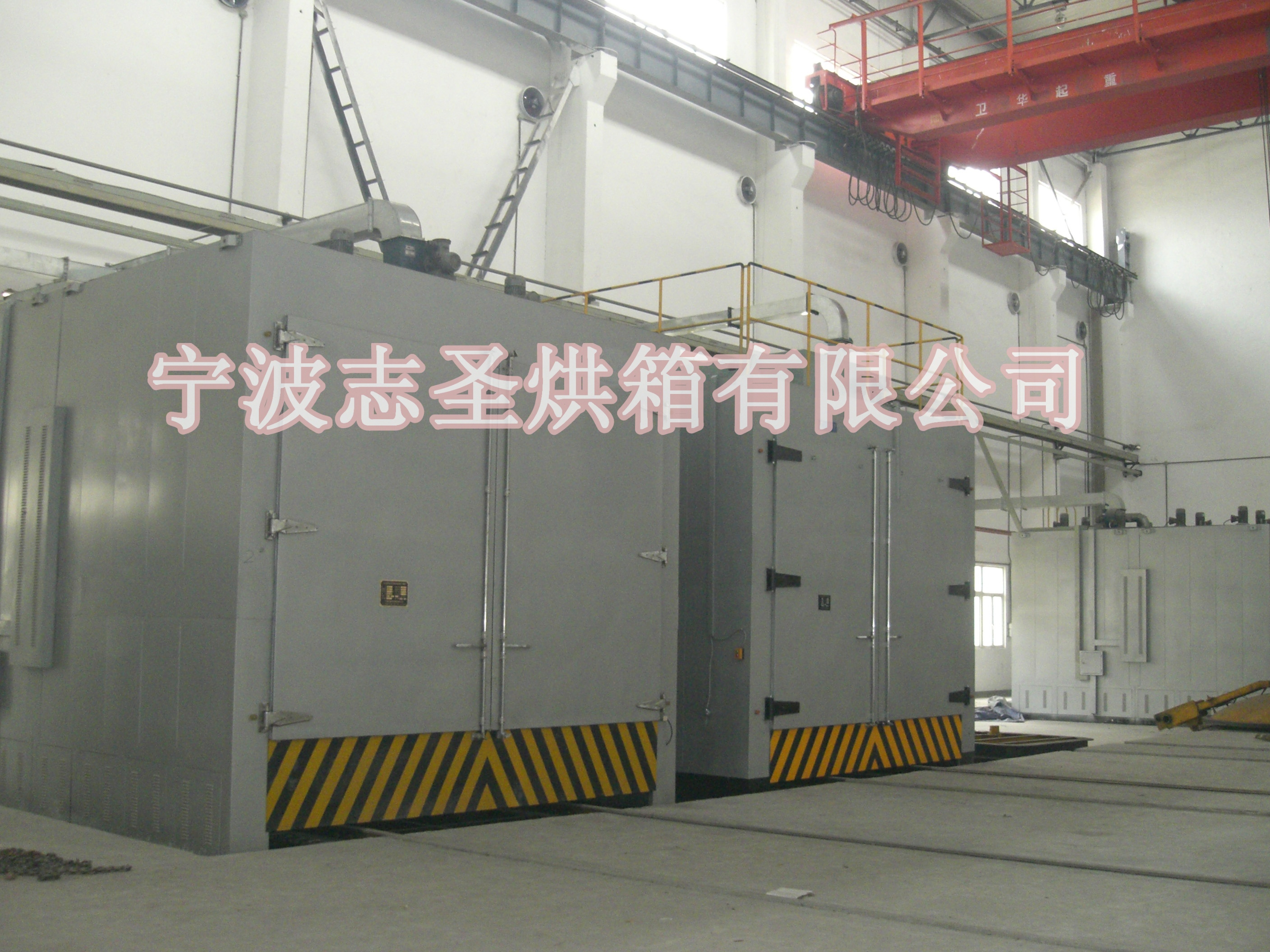

It is used to realize motor stator/rotor static rotation curing and is widely used in production of wind turbine, marine motor, high voltage motor, large ac/dc motor and special motor.

To solve the problem of uneven hanging paint of stator/rotor during static curing which affects the electrical properties of the product.

The surface is wound sheet type low load electric heating tube, so the surface temperature is always below 350 ℃, which eliminates combustion and explosion hazards

High air volume strong exhaust ventilation makes the concentration of dangerous gases inside the oven always in a safe range

Exhaust wind pressure is under detection and alarm and it will automatically stop the heating when the gas exhaust is abnormal

Large areas of explosion venting door can make the loss reduced to the minimum when accidents occur

Strong exhaust fan/circulation fan/heating electric power interlocking control

High temperature combustible gas detection,control and alarm (optional)

Highly efficient and energy-saving heat exchanger: recycling effluent heat

Thermal insulation material: the thermal insulated surface temperature of high quality aluminum silicate wool Insulation has to be less than the indoor temperature plus 15℃

Temperature evenness increased to + / - 5 ℃ range; which can guarantee the quality of your product

Configuration software, computer distributed control, PLC touch screen control, paperless recording, insulation resistance testing, VOC dangerous gas detector, wind pressure sensor...

| Parameter | HA-1J/1X | HA-2J/2X | HA-3J/3X | HA-4J/4X | HA-5J/5X |

| Dimension of working chamber (width x depth x height)mm | 1800×2600×1700 | 2000×3000×2000 | 2000×4000×2000 | 2500×5000×2500 | 5000×6000×3500 |

| Operating temperature(℃) | Indoor temperature--250 | Indoor temperature--250 | Indoor temperature--250 | Indoor temperature--250 | Indoor temperature--250 |

| Operating voltage/frequency (V/ Hz) | 3-380/50 | 3-380/50 | 3-380/50 | 3-380/50 | 3-380/50 |

| Heating power (kw) | 54 | 72 | 90 | 125 | 320 |

| Temperature uniformity (%) | ±2.5 | ±2.5 | ±2.5 | ±2.5 | ±2.5 |

| Temperature fluctuation (℃) | ±1 | ±1 | ±1 | ±1 | ±1 |

| Ventilation volume (M3/H) | 700 | 1000 | 1500 | 3500 | 8000 |

| Dissolvent discharge capability(L/H) | 3.5 | 5.0 | 7.0 | 15 | 35 |

| Heat transfer efficiency(%) | 80 | 80 | 80 | 80 | 80 |

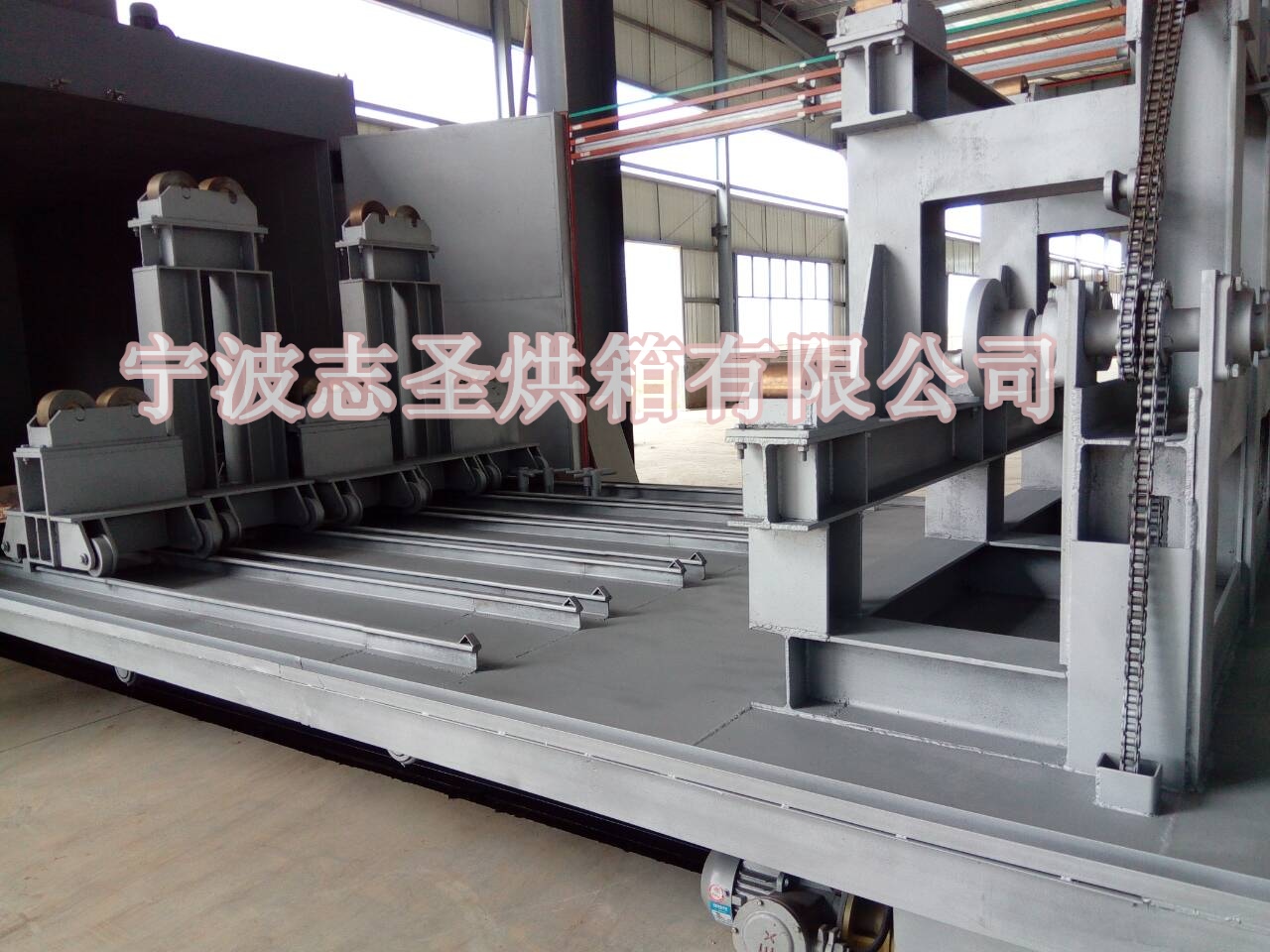

| Trolley rotation | Roller/riding wheel | ||||

| Velocity of rotation | 0.5~5rpm frequency control | ||||

| Weight(T) | 4.5 | 6.0 | 8.0 | 15 | 35 |

Annotation:① Non-standard product can be designed and manufactured in accordance with the requirement of the user;② Heat transmission effectiveness only applies to the high security and energy-saving drying oven | |||||