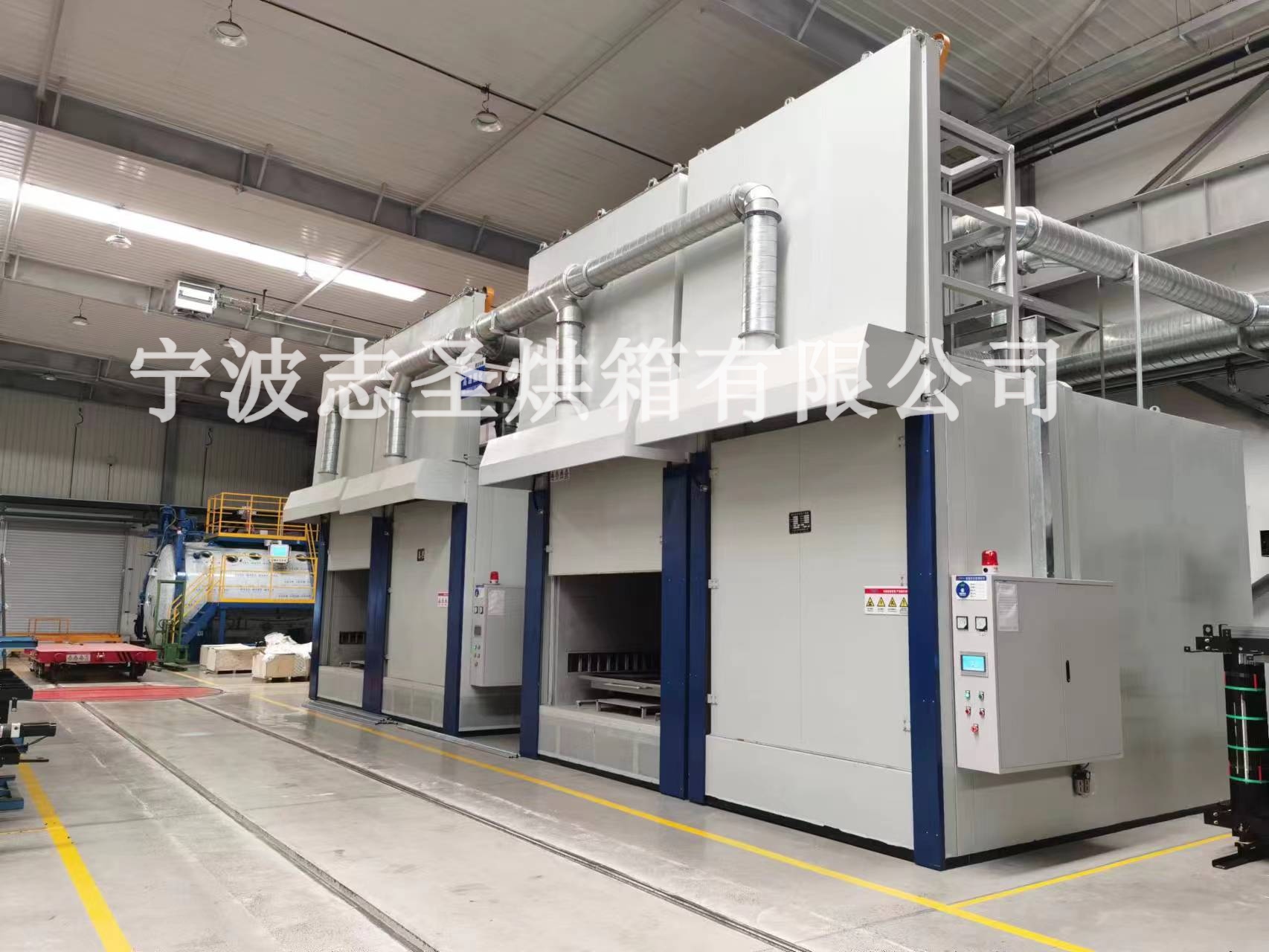

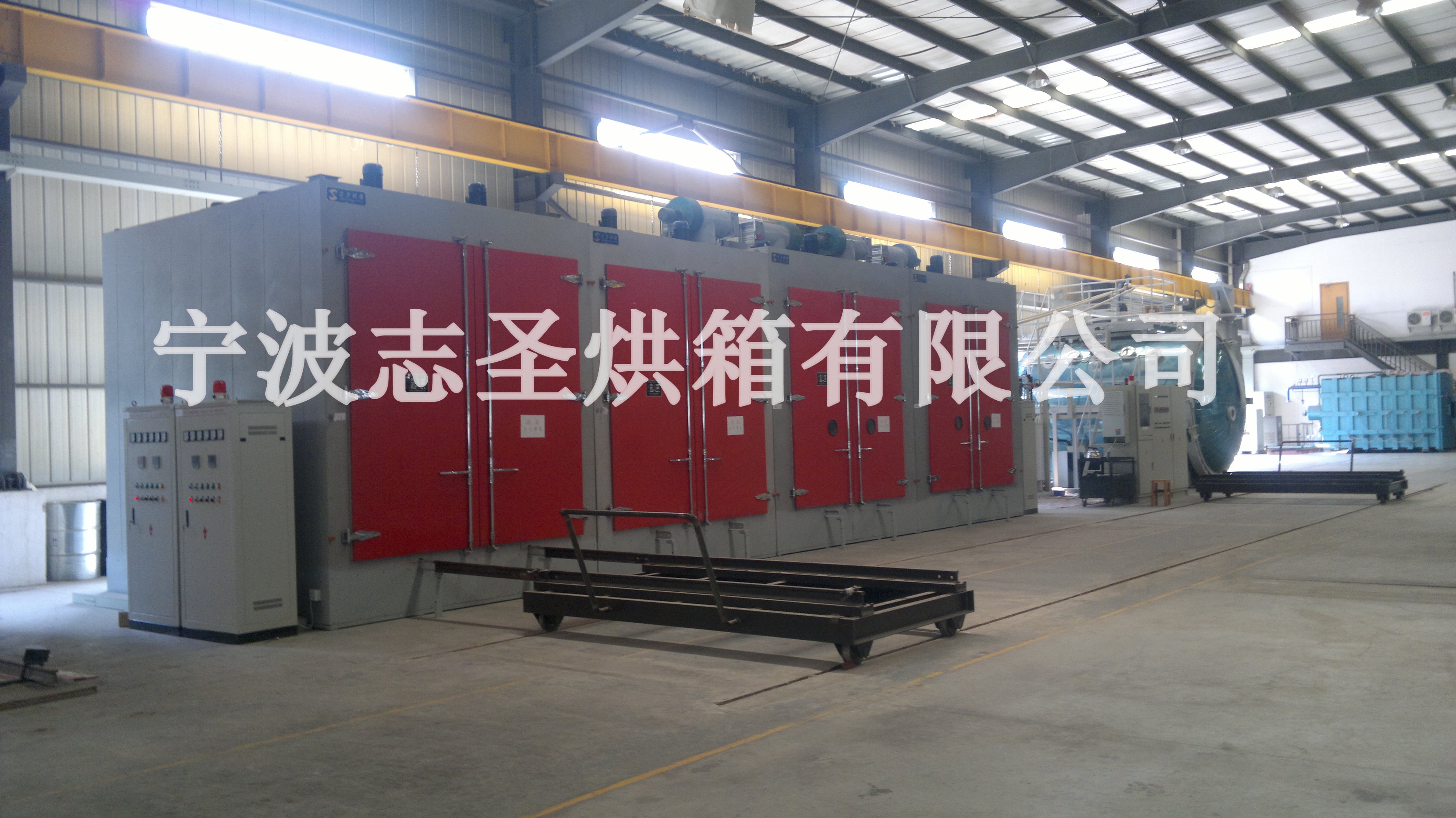

HB-T series transformer inverted gradient curing furnace is a new generation of special electric heating equipment specially developed and designed for the manufacturers of dry type transformer by our company, which combined advanced technology at home and abroad, it is independently developed by our company and the company own its intellectual property rights.

Preferrably, the temperature distribution in the furnace should be gradient from bottom to top and that temperature distribution can be controlled by the requirement according to the characteristics of dry production process when epoxy resin is in the initial stage of gel curing, which will effectively reduce such micro defects as cracks and small bubbles caused by internal stress of epoxy resin, which will guarantee that the products' partial discharge wil always be in a safe range. And that is why HB series inverted gradient curing oven is the ideal new generation upgrade products of dry type curing equipment in the industry. At present, the curing furnace has been widely used in the transformer industry and well-received by the majority of customers.

It has all the functions of ordinary curing furnace.

Develpoped by our company, the curing furnace has adopted our own patented technology, which is the leading technology in China.

Full cycle air exchange mode and unique hot air circulation system enable the temperature in the furnace to achieve gradient temperature rise in the gel phase of the production to achieve the most perfect process of curing epoxy resin.

New air exchange function makes possible curve control of temperature rise and fall.

| Parameter | HB-1T | HB-2T | HB-3T | HB-4T | HB-5T |

| Dimension of working chamber(width×depth×height) mm | 2000×2000×2000 | 2000×3000×2000 | 2000×3500×2000 | 2000×4000×2000 | 3000×5000×3000 |

| Operating temperature(℃) | Indoor temperature—200 | Indoor temperature—200 | Indoor temperature—200 | Indoor temperature—200 | Indoor temperature—200 |

| Operating voltage/frequency(V/ Hz) | 3—380/50 | 3—380/50 | 3—380/50 | 3—380/50 | 3—380/50 |

| Heating power(kw) | 57 | 78 | 87 | 99 | 135 |

| Temperature uniformity(%) | ±2.5 | ±2.5 | ±2.5 | ±2.5 | ±2.5 |

| Temperature fluctuation(℃) | ±1 | ±1 | ±1 | ±1 | ±1 |

| Weight(T) | 3.5 | 5 | 5.5 | 7.5 | 9.5 |

Note: Non-standard product can be designed and manufactured in accordance with the requirement of the user. | |||||