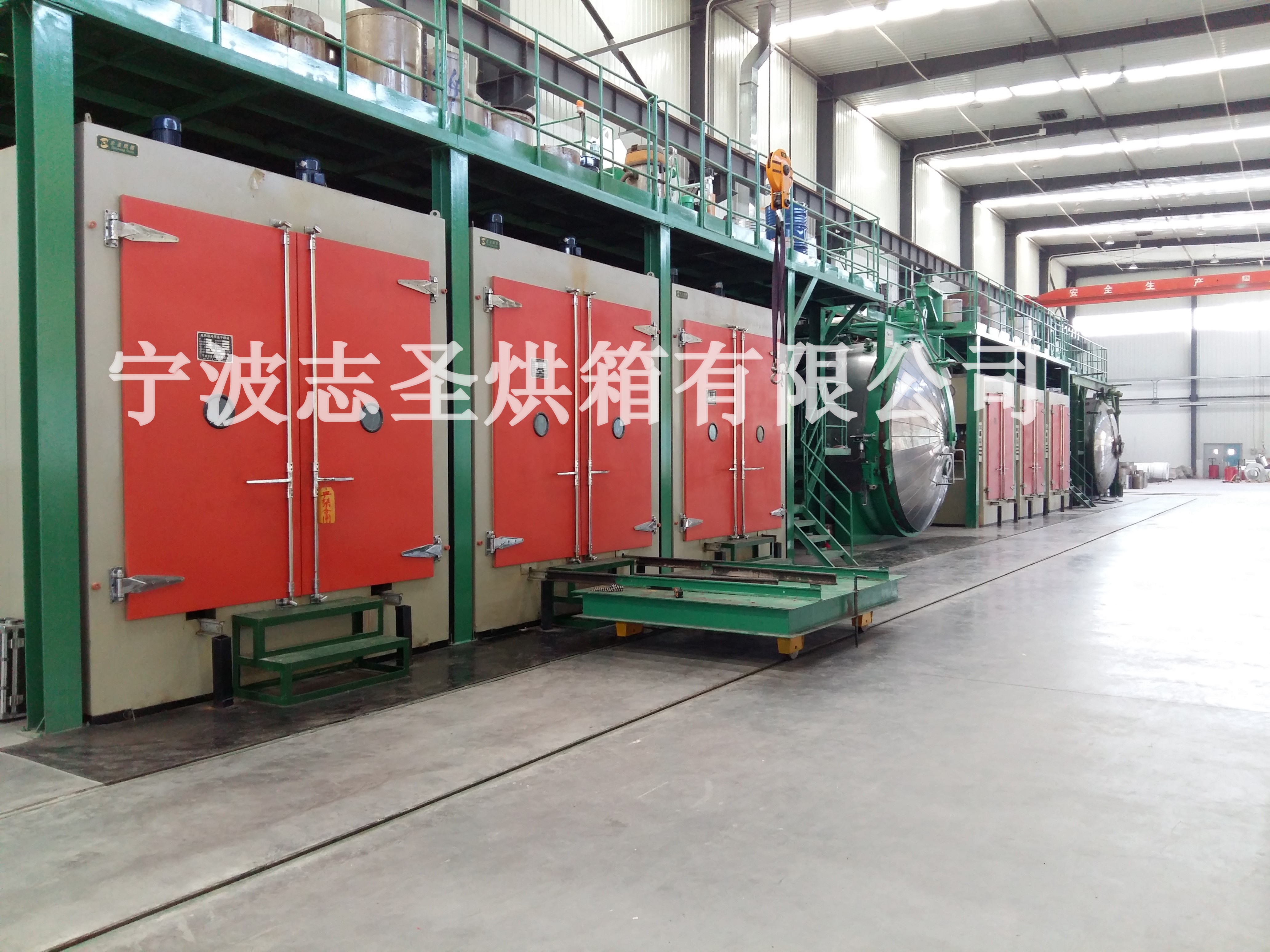

HB series transformer curing furnace is a specialized curing equipment independently developed and designed by our company according to the working principle of curing furnace combined with our extensive experience in transformer industry, it’s characteristic of excellent temperature uniformity, outstanding performance in thermal insulation and pleasant apperance.Hb series transformer is widely used in curing process after dry coil epoxy casting, vacuum paint dipping and winding; pre-drying of molds and coils; and the transformer drying.

Two sets of over temperature alarm systems ensures the operation safety of the curing furnace.

You can select a reasonable hot air circulation mode according to the product layout, so as to make the temperature in the furnace more uniform and the curing (drying) effect more remarkable.

With advanced electrical control, with intelligent program temperature controller and PID parameters self-tuning, solid-state relay power adjusting system, any curing curve can be set up according to different processes, and it is easy to operate and the performance is realiable.

High quality aluminum silicate cotton insulation with low thermal conductivity and unique insulation cotton filling method ensure the insulation performance of the curing furnace.

The accessories of this series of curing furnace standard configuration are manual pallet and tracks inside and outside the furnace.

Optional accessories includes automatic trolley, low-voltage lighting and observation window in furnace, temperature recorder, computer distributed control system, etc.

| Parameter | HB-1 | HB-2 | HB-3 | HB-4 | HB-5 | HB-6 |

| Dimension of working chamber mm(width×depth×height) | 1400×1550×1400 | 2000×2000×2000 | 2000×3000×2000 | 2000×3500×2000 | 2000×4000×2000 | 3000×5000×3000 |

| Operating temperature(℃) | indoor temperature-200 | indoor temperature-200 | indoor temperature-200 | indoor temperature-200 | indoor temperature-200 | indoor temperature-200 |

| Operating voltage/frequency(V/ Hz) | 3—380/50 | 3—380/50 | 3—380/50 | 3—380/50 | 3—380/50 | 3—380/50 |

| Heating power(kw) | 24 | 45 | 60 | 66 | 72 | 108 |

| Temperature uniformity(%) | ±2.5 | ±2.5 | ±2.5 | ±2.5 | ±2.5 | ±2.5 |

| Temperature fluctuation(℃) | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 |

| Weight(T) | 1.5 | 3 | 4 | 4.5 | 6 | 8 |

Note: Non-standard product can be designed and manufactured in accordance with the requirements of the user. | ||||||