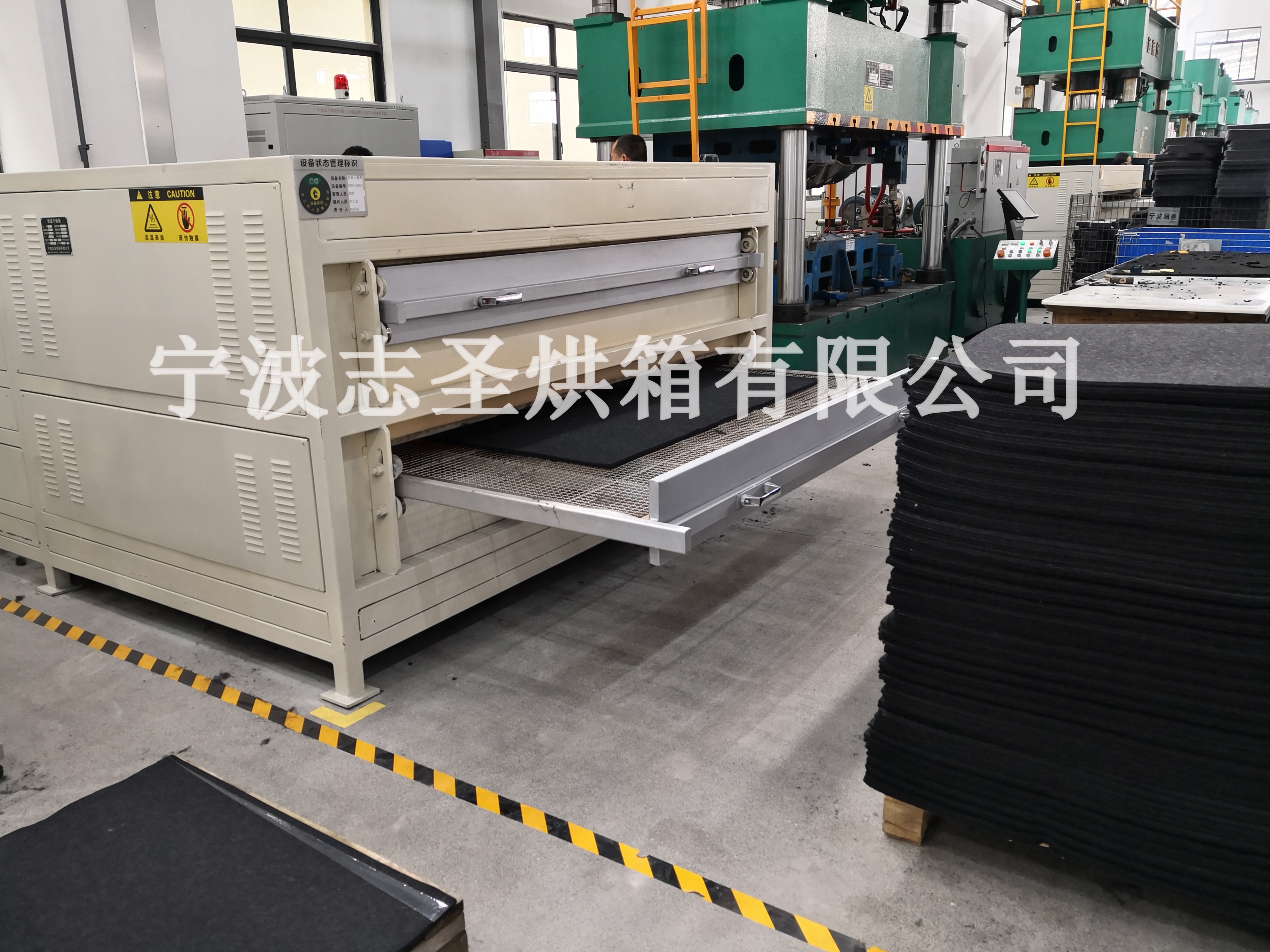

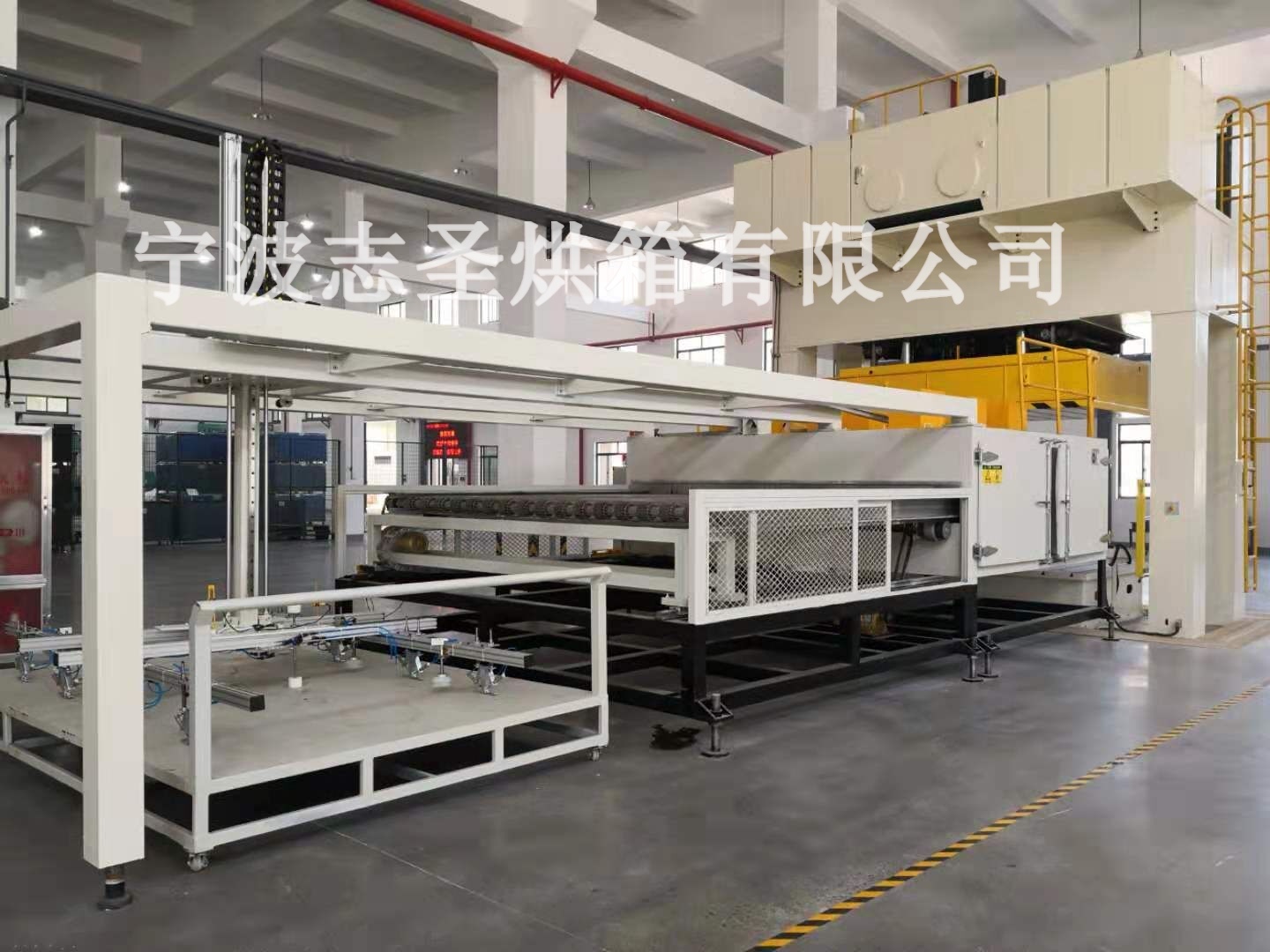

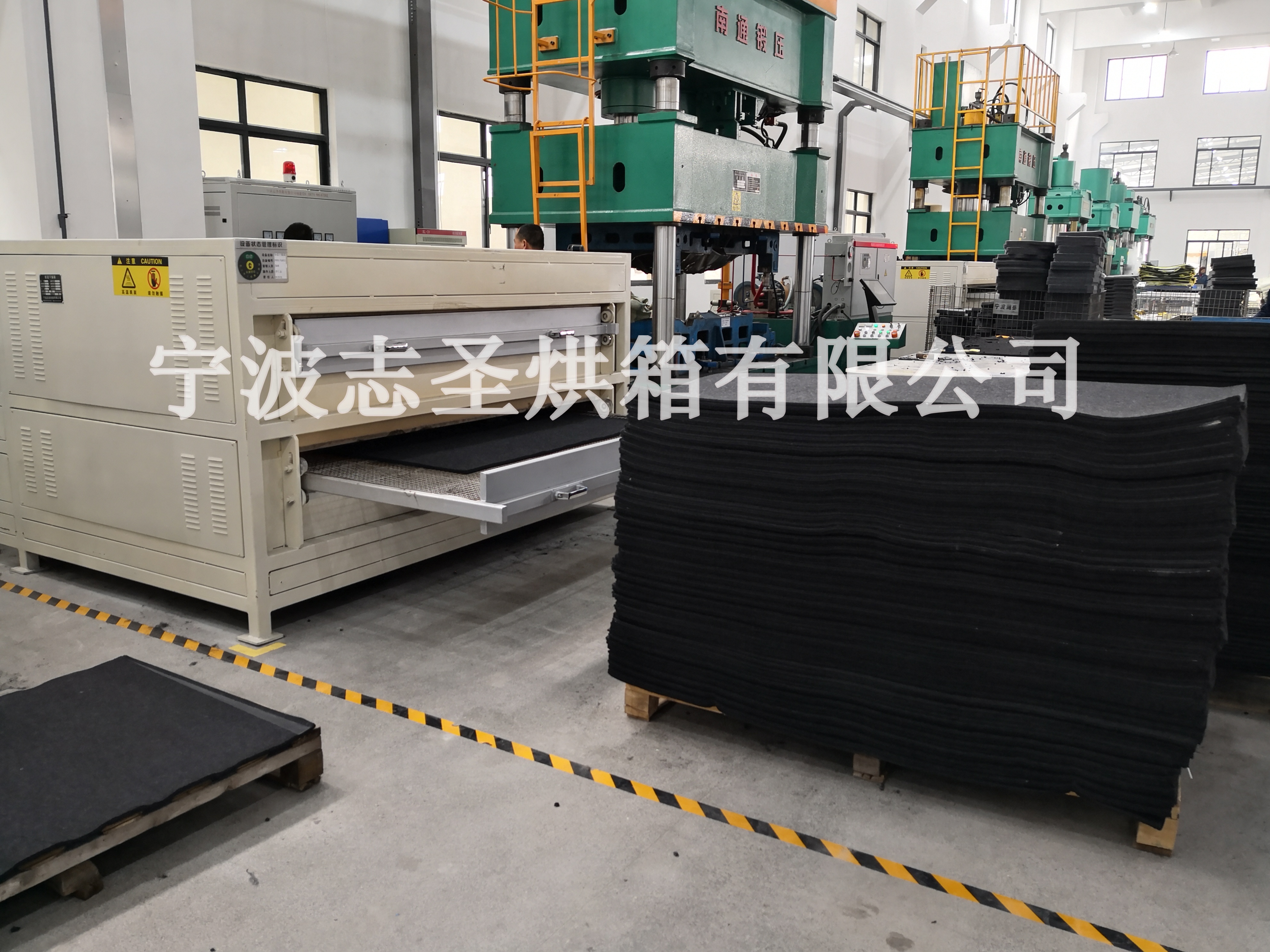

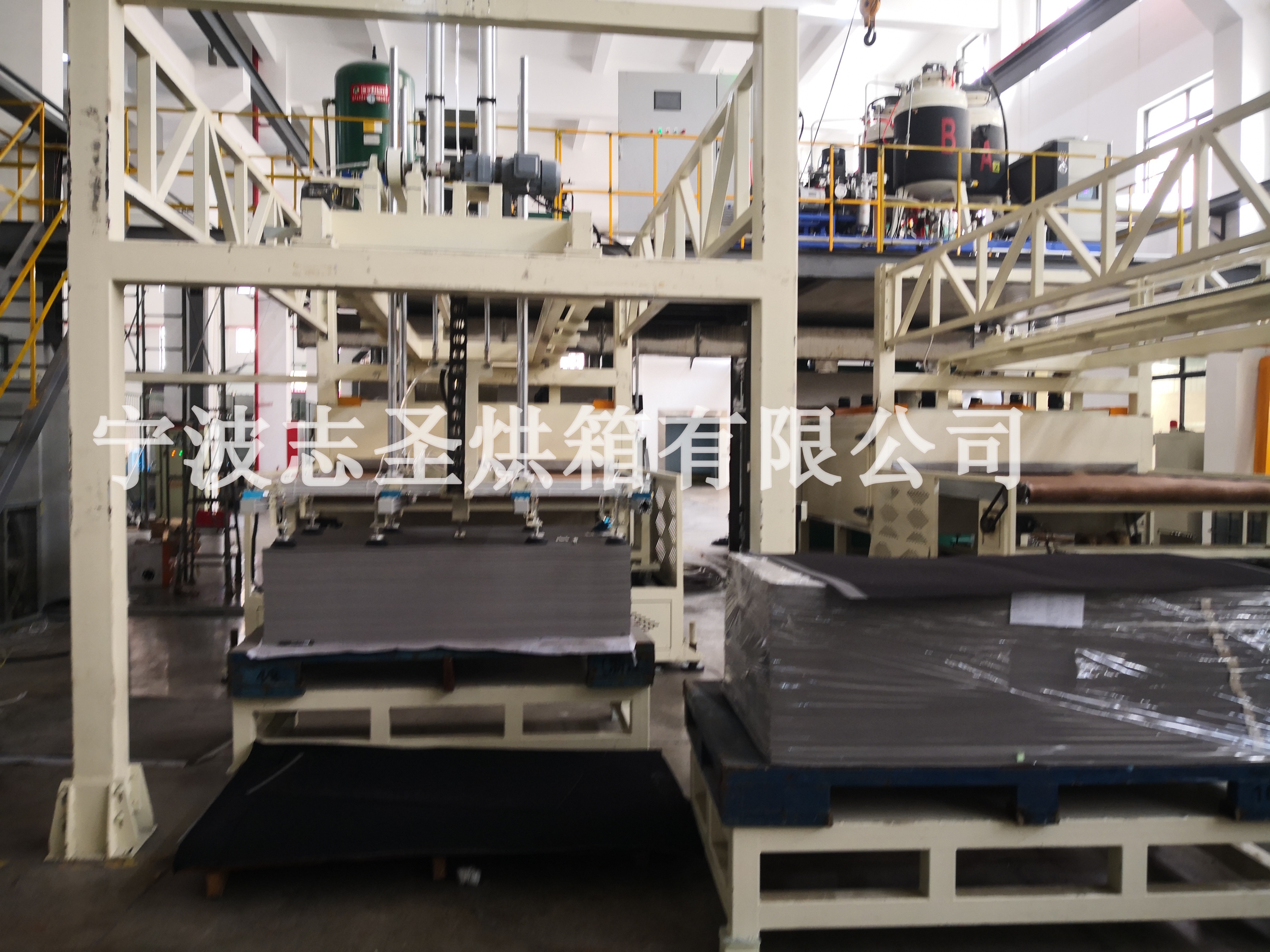

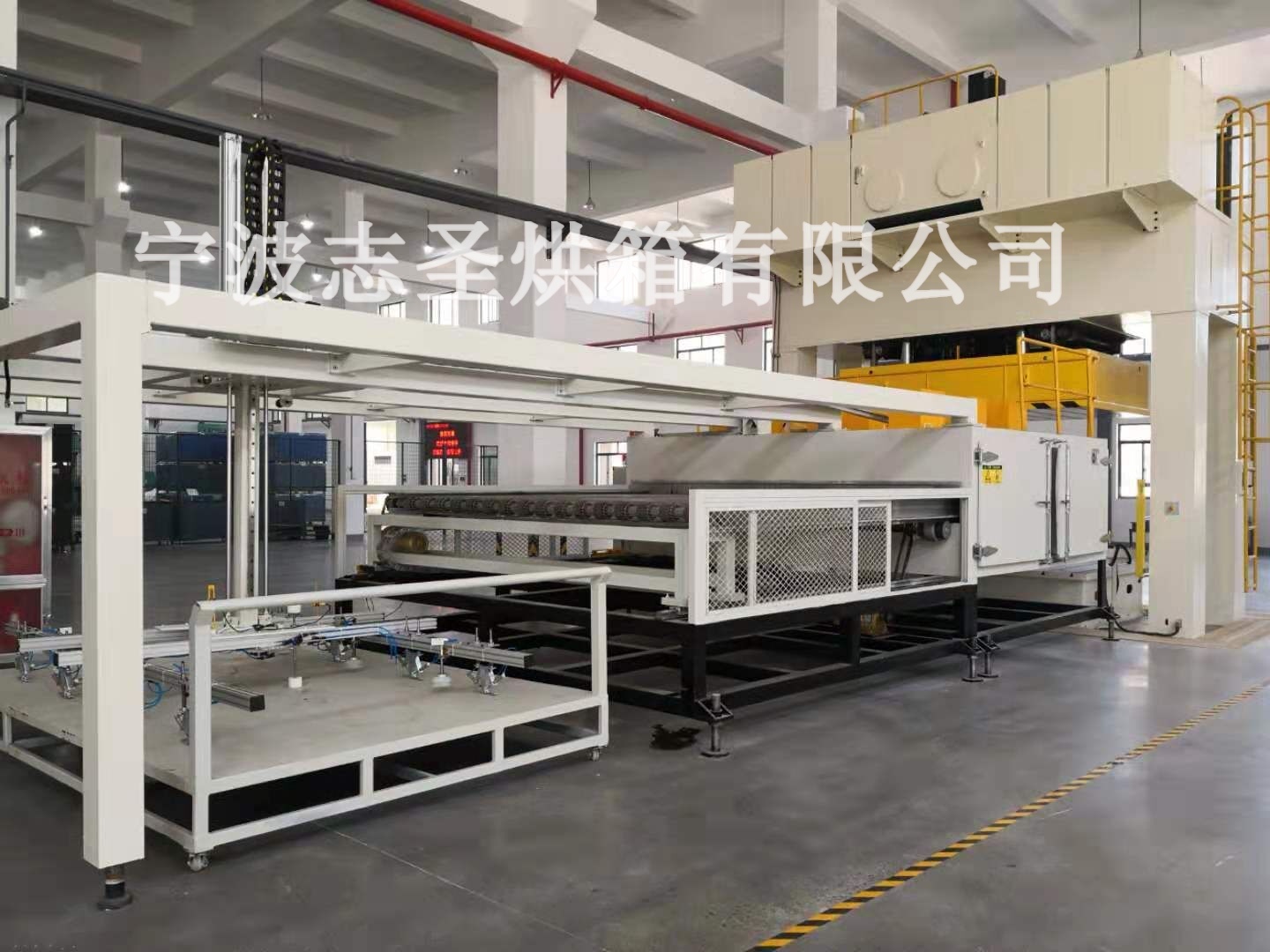

This series of products are mainly used for pre-baking of thermoplastic sheet, PU composite board, EVA sheet, EPDM, XPE, composite PVC, corrugated board, glass fiber and other sheet materials and PP wood powder base materials (including ceiling, instrument panel, carpet and other interior decorations) before molding by automobile interior decoration manufacturers.

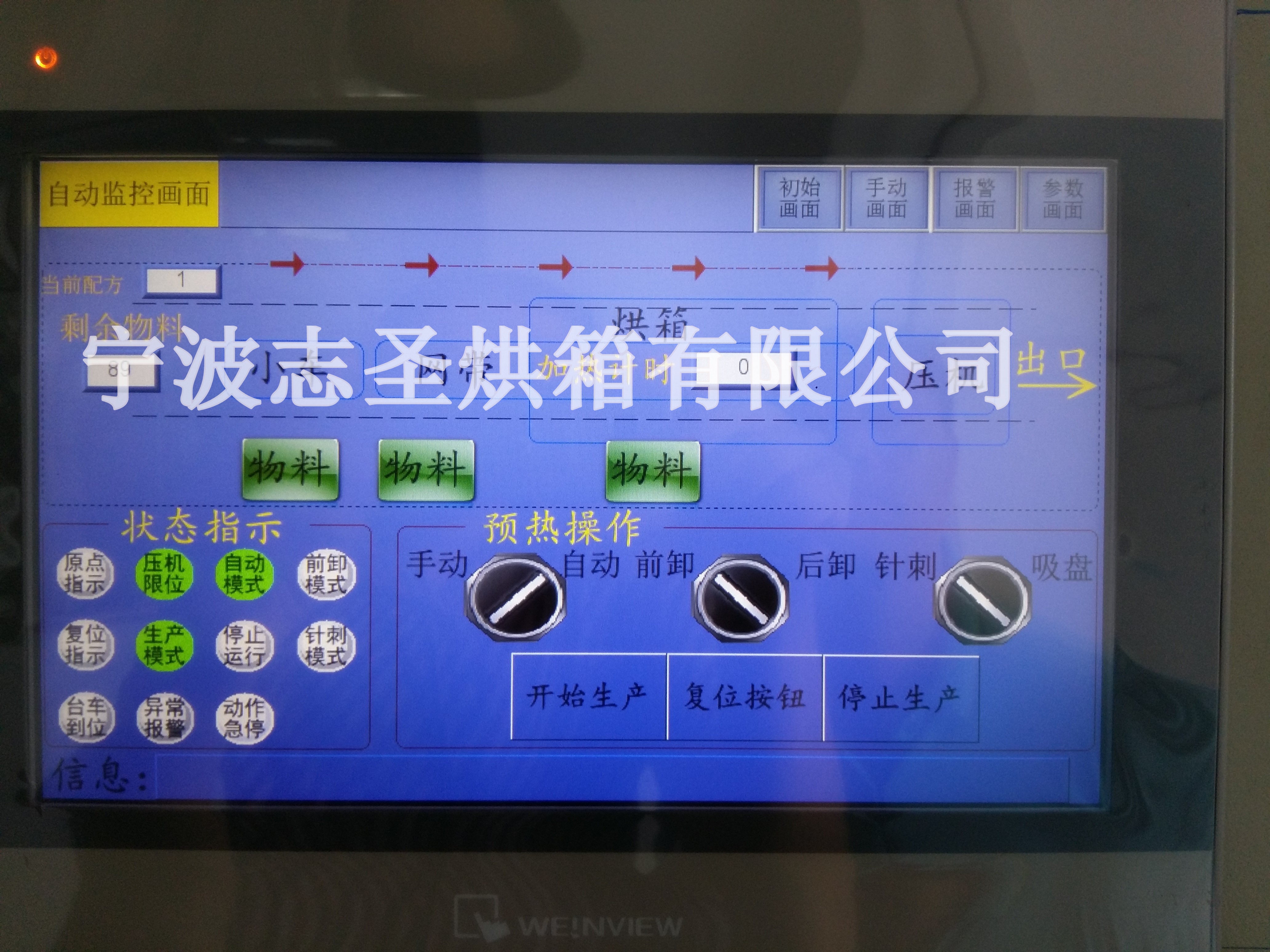

The equipment adopts the upper and lower double-sided high infrared tube radiation heating mode or ceramic heating tile radiation heating mode,you can choose the time control mode or temperature control mode.

Temperature control is uniform in each area with good thermal insulation. The structure design is reasonable, so the feeding positioning is accurate, all of which leads to high production efficiency.

| Parameter | HN-1 | HN-2 | HN-3 | HN-4 | HN-5 |

| Dimension of working chamber mm(width×depth×height) | 1820×1400×400 | 2850×1800×400 | 1980×2500×400 | 3570×2090×400 | 4270×2090×400 |

| Operating temperature(℃) | Indoor temperature—350 | Indoor temperature—350 | Indoor temperature—350 | Indoor temperature—350 | Indoor temperature—350 |

| Operating voltage/frequency(V/ Hz) | 3—380/50 | 3—380/50 | 3—380/50 | 3—380/50 | 3—380/50 |

| Heating frequency(kw) | 49.5 | 72 | 76.5 | 94.5 | 121.5 |

| Temperature uniformity(%) | ±2.5 | ±2.5 | ±2.5 | ±2.5 | ±2.5 |

| Temperature fluctuation(℃) | ±1 | ±1 | ±1 | ±1 | ±1 |

| Weight(T) | 1.5 | 2.5 | 2.7 | 3.2 | 3.5 |

| Note: Non-standard product can be desgined and manufactured in accordance with the requirement of the user. | |||||